- Joined

- Oct 31, 1996

- Posts

- 1,502

- Type aircraft owned

- Carbon Cub FX-3

- Base airport

- KFCI

- Ratings

- COMM, IFR, MEL, SEL

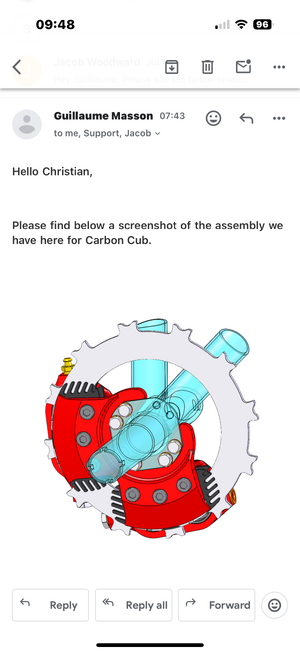

I have a 2023 FX-3 with 31 inch bush tires. It is a well known issue that Beringer 6 inch brakes, which I ordered for my cub, will not perform as expected and can barely hold for engine runup. In 2021 we went through quite a bit to resolve this on my first FX-3 and improved it by using Beringer brake lines instead of CubCrafters' version and all of the metric to imperial fittings that had to be added. We replaced brake pads at 10 hours and struggled to resolve the issue. On my 2023 cub, soon after delivery, I spoke with Beringer at Oshkosh and they informed me that the reason, according to them, is the CubCrafters rudder pedals were not tall enough for the correct master cylinders for the job, so smaller masters are being used. They said CubCrafters would be coming out with correct size rudder pedals, which to date I haven't heard of, and quite frankly wouldn't expect as they are very slow to change anything, if at all. But Beringer told me the answer to the problem is the new dual caliper brake system which I purchased immediately after returning from Oshkosh and installed and it made a huge difference, braking is now as it should be.

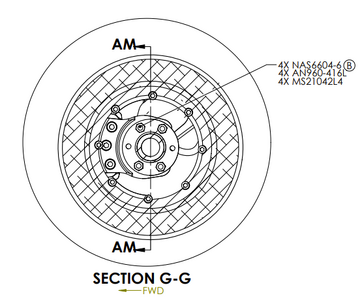

@Cubonaut875 also bought the dual calipers but has yet to install them and prior to going to Oshkosh this year he dropped his plane off with his A&P to have the dual caliper brakes installed. His A&P realized the holes weren't lining up for the bolts as outlined and only 3 would line up. And that's what I installed with mine, the 3 bolts. His A&P reached out to Pete at CubCrafters who stated 3 is insufficient. His A&P reached out to me and I mentioned it's a sheer force, and I've had no issues to date, I'm fine with it, however, is drilling out additional holes an option? He preferred the correct backing plate, as our 6-hole axles are welded per Pete, that's not an option to change, so Beringer would need to have a compatible backing plate for this axle. I find it interesting that CubCrafters specs out 4 bolts for the single caliper install on the 6 hole axle, yet in their opinion 6 bolts is needed for the dual caliper setup.

In discussion with Pete he pointed out the use of a stronger sheer force bolt (NAS...) instead of an AN bolt, which ironically is what was installed with my Beringer's from the factory it seems. So I ordered more bolts, washers, and the special nuts used in this job with intent of drilling out more holes in my install.

I don't recall if checking the brakes during condition inspection is on the AMM checklist but I am glad I pulled my wheels off as the brakes were full of yuck and needed cleaning, the pistons on the Beringer's were not fully retracted on one side so I reached out to my dealer and he said to just push them back in. I should have removed them and re-lubed them, but that's for next time. My right side wheel was also not free spinning, it was binding due to this piston issue. So the lesson learned is, IMHO, your brakes need to be inspected at condition inspections. I know the A&P I used back in 2022 at a CubCrafters service center did not and quite frankly that inspection was so lacking I never returned.

So in pulling the brakes apart for a good cleaning I drilled one additional hole (green arrow below) which is all that could be drilled. Thankfully it's in the Beringer part and not on the welded backing plate. I'd hate to screw that up! It's not the best engineering work but I now have a 4th bolt in my install. I'll reach out to Beringer about this too as they really need a proper mounting plate for the CubCrafters 6 hole axle. CubCrafters does not have engineering data for Beringer dual calipers and believes 6 bolts should be used as outlined by Beringer.

While at this I replaced my brake pads with the newer style from Beringer which they call STOL competition brake pads I believe. You can see they have cooling fins that protrude off the sides. My brake pads are probably fine but I really don't want to do this again for a long time so I'm just installing the new pads I bought when the release announcement about these came out. If I recall it's about $100 per pad (ouch).

FYI - I had to drain the brake fluid, i.e. release pressure, to do this work. I spent 4 hours fighting this job yesterday as I couldn't get the wheel to align and mate with the brake disk, come to find out it was just not realizing how to work this back together after fiddling with the brake pads and slowly tightening the axle nut while rotating the wheel allowed things to align and mate up properly.

Tomorrow I'll complete the job with the safety wire around the brake disk and re-bleed the brakes. Not a fun task and a very dirty one at that but always good to be able to do this stuff yourself. Now if only Beringer can get the proper backing plate to work with the CubCrafters 6 hole axle all the better but I'm not optimistic that will happen. There is also some talk of a new single caliper design. Just realize when you have Beringer single caliper brakes paired with 31 inch bush wheels on the 6 inch brake setup, braking isn't great. For a cub, that doesn't matter much, you shouldn't need brakes other than runup or STOL competitions. Based on the amount of build up I had in my brakes I'll probably use brakes less now that I did before as I routinely would use them and had no problem with that. I'll gladly replace pads when needed. But now I'll reconsider that.

NOTE: It seems I did not take a picture of the finished job showing 4 bolts now in use.

@Cubonaut875 also bought the dual calipers but has yet to install them and prior to going to Oshkosh this year he dropped his plane off with his A&P to have the dual caliper brakes installed. His A&P realized the holes weren't lining up for the bolts as outlined and only 3 would line up. And that's what I installed with mine, the 3 bolts. His A&P reached out to Pete at CubCrafters who stated 3 is insufficient. His A&P reached out to me and I mentioned it's a sheer force, and I've had no issues to date, I'm fine with it, however, is drilling out additional holes an option? He preferred the correct backing plate, as our 6-hole axles are welded per Pete, that's not an option to change, so Beringer would need to have a compatible backing plate for this axle. I find it interesting that CubCrafters specs out 4 bolts for the single caliper install on the 6 hole axle, yet in their opinion 6 bolts is needed for the dual caliper setup.

In discussion with Pete he pointed out the use of a stronger sheer force bolt (NAS...) instead of an AN bolt, which ironically is what was installed with my Beringer's from the factory it seems. So I ordered more bolts, washers, and the special nuts used in this job with intent of drilling out more holes in my install.

I don't recall if checking the brakes during condition inspection is on the AMM checklist but I am glad I pulled my wheels off as the brakes were full of yuck and needed cleaning, the pistons on the Beringer's were not fully retracted on one side so I reached out to my dealer and he said to just push them back in. I should have removed them and re-lubed them, but that's for next time. My right side wheel was also not free spinning, it was binding due to this piston issue. So the lesson learned is, IMHO, your brakes need to be inspected at condition inspections. I know the A&P I used back in 2022 at a CubCrafters service center did not and quite frankly that inspection was so lacking I never returned.

So in pulling the brakes apart for a good cleaning I drilled one additional hole (green arrow below) which is all that could be drilled. Thankfully it's in the Beringer part and not on the welded backing plate. I'd hate to screw that up! It's not the best engineering work but I now have a 4th bolt in my install. I'll reach out to Beringer about this too as they really need a proper mounting plate for the CubCrafters 6 hole axle. CubCrafters does not have engineering data for Beringer dual calipers and believes 6 bolts should be used as outlined by Beringer.

While at this I replaced my brake pads with the newer style from Beringer which they call STOL competition brake pads I believe. You can see they have cooling fins that protrude off the sides. My brake pads are probably fine but I really don't want to do this again for a long time so I'm just installing the new pads I bought when the release announcement about these came out. If I recall it's about $100 per pad (ouch).

FYI - I had to drain the brake fluid, i.e. release pressure, to do this work. I spent 4 hours fighting this job yesterday as I couldn't get the wheel to align and mate with the brake disk, come to find out it was just not realizing how to work this back together after fiddling with the brake pads and slowly tightening the axle nut while rotating the wheel allowed things to align and mate up properly.

Tomorrow I'll complete the job with the safety wire around the brake disk and re-bleed the brakes. Not a fun task and a very dirty one at that but always good to be able to do this stuff yourself. Now if only Beringer can get the proper backing plate to work with the CubCrafters 6 hole axle all the better but I'm not optimistic that will happen. There is also some talk of a new single caliper design. Just realize when you have Beringer single caliper brakes paired with 31 inch bush wheels on the 6 inch brake setup, braking isn't great. For a cub, that doesn't matter much, you shouldn't need brakes other than runup or STOL competitions. Based on the amount of build up I had in my brakes I'll probably use brakes less now that I did before as I routinely would use them and had no problem with that. I'll gladly replace pads when needed. But now I'll reconsider that.

NOTE: It seems I did not take a picture of the finished job showing 4 bolts now in use.

Attachments

Last edited: